Your cart is currently empty!

Developing a cell and gene therapy (C>) product into a clinical format is a lengthy and costly process. The associated cost is in part due to the length of the process, and also due to the costly components of the process (personnel, material, equipment).

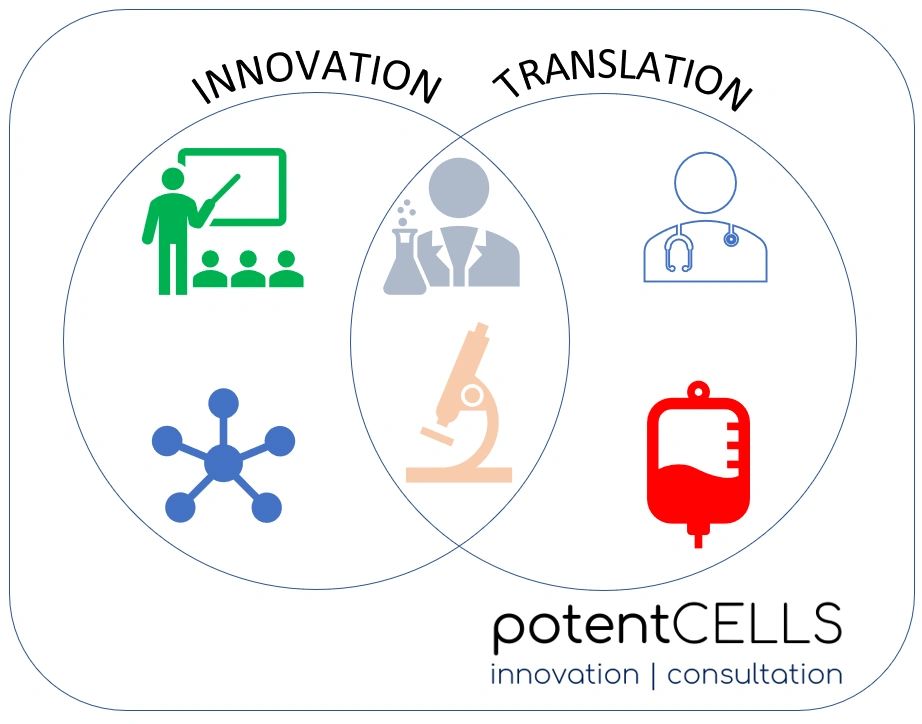

For C> products to be cost effective and reach those who need them, C> products need to be developed (from development to clinical production) on a regular basis. Such regularity in developing products requires an efficient system that can sustain itself, and therefore, can keep the cost at the minimum. There are two main components to this development system:

A. The innovation generator

The innovation generator is a multidisciplinary system designed to be self-sustaining with the capability to regularly produce innovations. The model that generates the most C> innovations is the academic model. This model is very efficient due to the following criteria:

- Fundamental Education: basic C> education and training is provided to students, which creates a steady flow of students with exposure to C> principles and techniques.

- Transient Manpower: the work force in academic center laboratories is mainly students who work to fulfill their graduation requirements. Older students would train the new ones on ongoing research studies. As a result, new students build new skills, research studies are advanced, and more scientific output is generated where innovations become a regular by product.

- Shared Facilities: academic centers usually maintain cores of specialized equipment that researchers from different laboratories can utilize. By making them central, the maintenance/care activities are standardized which reduces the overall operation cost. Also, expensive equipment would be fully utilized increasing their return on investment.

With trained students taking part in ongoing research studies and utilizing specialized equipment, the academic center creates a self-sustaining system that regularly generates innovations at a very low cost.

The system described above ensures the “product development” segment of cell therapy processes is secured; the cell therapy production facilities also need to come up with a comparable production model.

B. The translation hub

Innovations generated by researchers at the product development phase, need to be repackaged to suite the clinic. This is a major source of cost for C> products unless we utilize an efficient model that reduces the indirect cost as much as possible. A model that can sustain itself for clinical cell therapy production is a cell therapy production facility with a translational research capability. Such model is bi-disciplined and is capable of talking research (to researchers) and is also capable of talking clinical (to the clinic). The components of this model are:

- Researchers with (a) strong C> expertise and (b) translational research training. Such group have standardized their approaches and can employ them with minor modifications. This group can easily adopt new processes and translate them into a clinic-suitable format.

- Implementation group: is the group tasked with implementing new processes by developing all required documents and defining the materials and equipment. By standardizing the process, they develop documents such as material specifications, standard operating procedures, production records, and certificate of analysis. This group has optimized methods to identify process requirements and develop a system to meet the requirements.

- Production group: is the group trained on clinical production using the approved material, equipment, and documents. This group operate in a compliant manner, and have processes to prepare for production, to ensure uninterrupted production activities, and to do the follow up, reconciliation and product release.

So, what keeps the C> pipeline full?

No one component operates in vacuum, it is the cohesive efforts that lead to the desired results. For a continuous C> stream through the pipeline, we need an innovation generator that efficiently utilizes resources and regularly generate innovation. We also need a translational hub that translates innovations through their standardized methods and make clinical products.

Let us know if we missed anything, or if you would like a specific subject to be discussed, write to us.

About the author

Naseem Almezel, earned his MSc degree in Cellular Therapies in 2010, since then his career focus is to support Bone Marrow Transplant and Oncology programs. Naseem likes to work in the lab doing translational research, or in the cleanroom doing GMP production. When he is not working, Naseem likes to read and to spend time outdoors. Find more about Naseem here